Product Series

-

Custom CNC Wheel Lathe FMU650-Y50

Custom CNC Wheel Lathe FMU650-Y50 delivers unmatched precision for wheel repair, enhancing efficiency in automotive CNC machining operations.

-

Customized Multifunction Wheel CNC Machine CK6166Q

Multifunction Wheel CNC Machine – Designing and Manufacturing Wheel CNC Machine, Wheel Repair Machine and Brake Drum Lathe. Looking for partners.

-

Customized CNC Vertical Wheel Machining Center

Vertical Wheel Machining Center delivers unmatched precision for wheel repair, enhancing efficiency in automotive CNC machining operations.

-

T8465 Car Brake Disc Lathe Machine

Brake Disc Lathe Machine – Manufacturing and supplying Wheel CNC Machine, Wheel Repair Machine, Brake Drum Lathe. Looking for dealers around the world.

-

T8445 Brake Drum Lathe machine

Brake Drum Lathe machine T8445 – Supplying Wheel CNC Machine, Wheel Repair Machine, Brake Drum Lathe. Looking for dealers around the world.

-

Car Brake Disc Lathe C9335

Brake disc lathe C9335 – Manufacturing and supplying Wheel CNC Machine, Wheel Repair Machine, Brake Drum Lathe. Looking for dealers around the world.

-

CNC Wheel Machine, Wheel Repair Lathe, Brake Drum Lathe

CNC Wheel machine – Designing and manufacturing wheel CNC machine, wheel repair machine, brake drum lathe and customized CNC machine. Looking for dealers.

-

RSM695 Wheel Straightening Repair Machine

Wheel Straightening Repair Machine – Supplying Wheel CNC Machine, Wheel Repair Machine and Brake Drum Lathe. Looking for dealers around the world.

-

RSM585 Manual Rim Straightening Machine

Rim Straightening Machine RSM585 – Manufacturing and Supplying Wheel CNC Machine, Wheel Repair Machine and Brake Drum Lathe. Looking for Partners.

-

Newest Wheel Repair Machine

Precision wheel repair machine for 10″-26″ rims, offering high-pressure performance and adaptable voltage for superior restoration

-

Automatic Rim Straightening Lathe machine RSM595

Rim straightening Lathe machine – Manufacturing and Supplying Wheel CNC Machine, Wheel Repair Machine, Brake Drum Lathe and customized CNC lathe.

-

High Performance Car Wheel CNC Lathe Machine CK6160A

Wheel CNC Lathe Machine CK6160A – Supplying Wheel CNC Machine, Wheel Repair Machine, Brake Drum Lathe. Looking for dealers around the world.

-

High Efficiency Alloy CNC Wheel Lathe Machine CK6166A

CNC Wheel Lathe Machine | Manufacturing and supplying Wheel CNC Machine, Wheel Repair Machine, Brake Drum Lathe. Looking for dealers around the world.

-

High Precision Car Wheel CNC Lathe CK6197W

Car Wheel CNC Lathe, Manufacturing and supplying Wheel CNC Machine, Wheel Repair Machine, Brake Drum Lathe. Looking for dealers around the world.

-

High Quality Economical Car Wheel Lathe CK6160Q

High Quality Economical Car Wheel Lathe CK6160Q – Specially engineered and fabricated for alloy car wheel repair and maintenance in Car Repair Workshops.

-

High Efficiency Vertical CNC Wheel Repair Lathe CKL-35

High Efficiency Vertical CNC Wheel Repair Lathe CKL-35 – The Newly developed Vertical Wheel Repair Lathe by HAISHU Machinery for alloy car wheel repair and super finishing. High quality, Competitive factory price.

-

Horizontal Wheel CNC Lathe CK6160W

Horizontal Wheel CNC Lathe CK6160W is a cost-effective, high-efficiency, high-gloss professional wheel lathe. High quality, competitive factory price.

-

Alloy Wheel Lathe With Laser Probe

Alloy wheel lathe is cost-effective, with automatic detection and precision optimization, and efficient chipping. Low price and high configuration.

-

New Type Pneumatic Door Underfloor Wheel Lathe

Underfloor Wheel Lathe is a new type of wheel CNC lathe, we provide you with customized services, and you only need 3 minutes to master

-

Newest Wheel Repair Lathe

Discover top-tier wheel repair lathe: precision CNC technology for efficient, reliable rim refurbishment and restoration.

-

Haas VF-3YT 50 Taper CNC VMC, 2007 – 4-Axis, 30 ATC, 2-Speed Gearbox

X-Axis Travel: 40″ Y-Axis Travel: 26″ Z-Axis Travel: 25″ Table Size: 54″ X 24″ Table Capacity: 3,500 lbs Rapid Traverse Rate (X/Y/Z): 710 IPM Spindle Speed: 7,500 RPM Spindle Motor: 30 HP Spindle Taper: CAT 50 Side Mount Tool Changer: 30 + 1 Positions Electrical Requirements: 208/230 V; 3 Ph; 50/60 Hz Approx Dimensions: 156″ x 102″ x 120″ Approx Machine Weight: 15,000 lbs EQUIPPED WITH: Haas CNC Control 2 Speed Gear Drive Extended Y-Axis Travel 4th Axis Drive Rigid Tapping Remote Jog Handle Programmable Coolant Chip Auger All Available Manuals Note: Vices not included. Haas rotary table pictured is not included.

$25,900.00

-

Ganesh VMC-4924 Vertical Machining Center, 2011 – 10K Spindle, 4th Axis Ready, Fanuc Oi Control

X-Axis Travel: 49″ Y-Axis Travel: 24″ Z-Axis Travel: 27″ Table Size: 50″ x 24″ Spindle Speed: 10,000 RPM Spindle Taper: CAT 40 Automatic Tool Changer: 24 Positions Electrical Requirements: 220 V; 3 Ph; 60 Hz Approx Machine Weight: 17,800 lbs Approx Dimensions (WxDxH): 126″ x 87″ x 128″ EQUIPPED WITH: Fanuc Oi CNC Control 4th Axis Ready 10,000 RPM Spindle 24 Position Side Mount Auto Tool Changer Remote Jog Handle Coolant Nozzle All Available Manuals

$24,900.00

-

Haas Mini Mill VMC, 2013 – Probing, Low Hours

X-Axis Travel: 16″ Y-Axis Travel: 14″ Z-Axis Travel: 15″ Table Size: 36″ x 12″ Spindle Nose to Table: 4″ – 19″ Max. Weight on Table: 500 lbs Feedrate Rapid Speed: 800 IPM Spindle Speed: 6,000 RPM Spindle Motor: 10 HP Taper: CAT40 Tool Capacity: 10 Tools Electrical Requirements: 208/240 V; 3/1 Ph; 50/60 Hz Full Load: 25/40 Amp Approx Dimensions: 90″ x 80″ x 92″ Approx Weight: 4,450 lbs. EQUIPPED WITH: Haas CNC Control WIPS- Wireless Intuitive Probing System 10 Position Automatic Tool Changer (Umbrella) All Available Manuals

$24,900.00

-

Tormach 1100MX VMC, 2024 – 4th Axis, Low Hours

X-Axis Travel: 18″ Y-Axis Travel: 11″ Z-Axis Travel: 16.25″ Spindle Power: 2 HP Max Spindle Speed: 10,000 RPM Table Size: 34″ × 9.5″ Max Weight on Table: 500 lbs Max Feed Rate – X/Y: 300 IPM Max Feed Rate – Z: 230 IPM Equipped With: Tormach CNC Control 4th Axis Rotary All Available Manuals

$29,900.00

-

Haas VF-7/40 VMC, 2011 – 4th Axis Ready, Chip Auger, Programmable Coolant

Table Size: 84″x28″ X-Axis Travel: 84″ Y-Axis Travel: 32″ Z-Axis Travel: 30″ Spindle Power: 20HP Spindle Speed: 7,500 RPM Spindle Taper: CAT 40 Tool Changer: 24 ATC Dimensions: 214″x102″x128.5″ Weight: 25,600lbs Equipped with: Haas CNC Control 4th-Axis Drive Chip Auger Programmable Coolant Jog Handle All Available Manuals

$65,900.00

-

Haas VF-6SS/40 VMC, 2009 – WIPS, 4th Axis Ready, Coolant Thru Spindle

Used Haas VF-6SS/40 VMC, 2009 Vertical Machining Center | WIPS, 4th Axis Ready, Coolant Thru Spindle This used Haas VF-6SS/40 from 2009 offers a robust solution for manufacturers requiring precision machining capabilities. With its expansive travel dimensions, this vertical machining center is well-suited for a variety of applications, particularly in aerospace, automotive, and general job shop environments. The Haas VF-6SS/40 features a high-speed spindle, which is complemented by an array of automation options, providing flexibility for production processes. Its coolant thru spindle capability is ideal for maintaining tool durability and reducing wear during extended runs. Additionally, the machine is equipped with a 4th axis ready configuration, allowing for enhanced machining versatility. Other key specifications include enhanced chip management systems that help maintain cleanliness and operational efficiency in your workplace. Buyers may also consider the Haas VF-4SS or the Haas VF-2SS for similar form factors and controls.

$39,900.00

-

Ganesh VMC-4020 Vertical Machining Center, 2007 – 10K Spindle, Fanuc Oi Control

X-Axis Travel: 40.9″ Y-Axis Travel: 21.1″ Z-Axis Travel: 21.1″ Table Size: 43.3″ x 18.7″ Spindle Speed: 10,000 RPM Spindle Taper: CAT 40 Automatic Tool Changer: 24 Positions Electrical Requirements: 220 V; 3 Ph; 60 Hz EQUIPPED WITH: Fanuc Oi CNC Control 24 Position Side Mount Auto Tool Changer Remote Jog Handle Coolant Nozzle All Available Manuals

$14,900.00

-

Haas VF-10/50 VMC, 2020 – TSC, Probe, 4th Axis

Table Size: 120″ x 28″ Table Load Capacity: 4,000 LBS X Axis Travel: 120″ Y Axis Travel: 32″ Z Axis Travel: 30″ Spindle Taper: CAT 50 Spindle Speed: 7500 RPM Spindle Motor: 30 HP ATC: 30+ 1 Approximant Weight 39,000 LBS Approximant Dimensions 260″ L x 101″ W x 128″ H Equipped With: Haas CNC Control Through-Spindle Coolant 4th-Axis Drive and Wiring HRT310 4th Axis Wireless Intuitive Probing System CNC Control Cabinet Cooler Enclosure Exhaust System High-Pressure Flood Coolant Through-Tool Air Blast High-Speed Machining Auxiliary Coolant Filter Chip Tray Filter Kit Window Air Blast WiFi Connection for the Haas Control Rigid Tapping Programmable Coolant Nozzle Remote Jog Handle with Touchscreen Display Media Display M-Code; M130 Lifting Provision HaasDrop HaasConnect: Remote monitoring Ethernet Interface Early Power-Failure Detection Module 95-Gallon Coolant Tank Standard Program Memory, 1 GB Chip Auger

$212,200.00

-

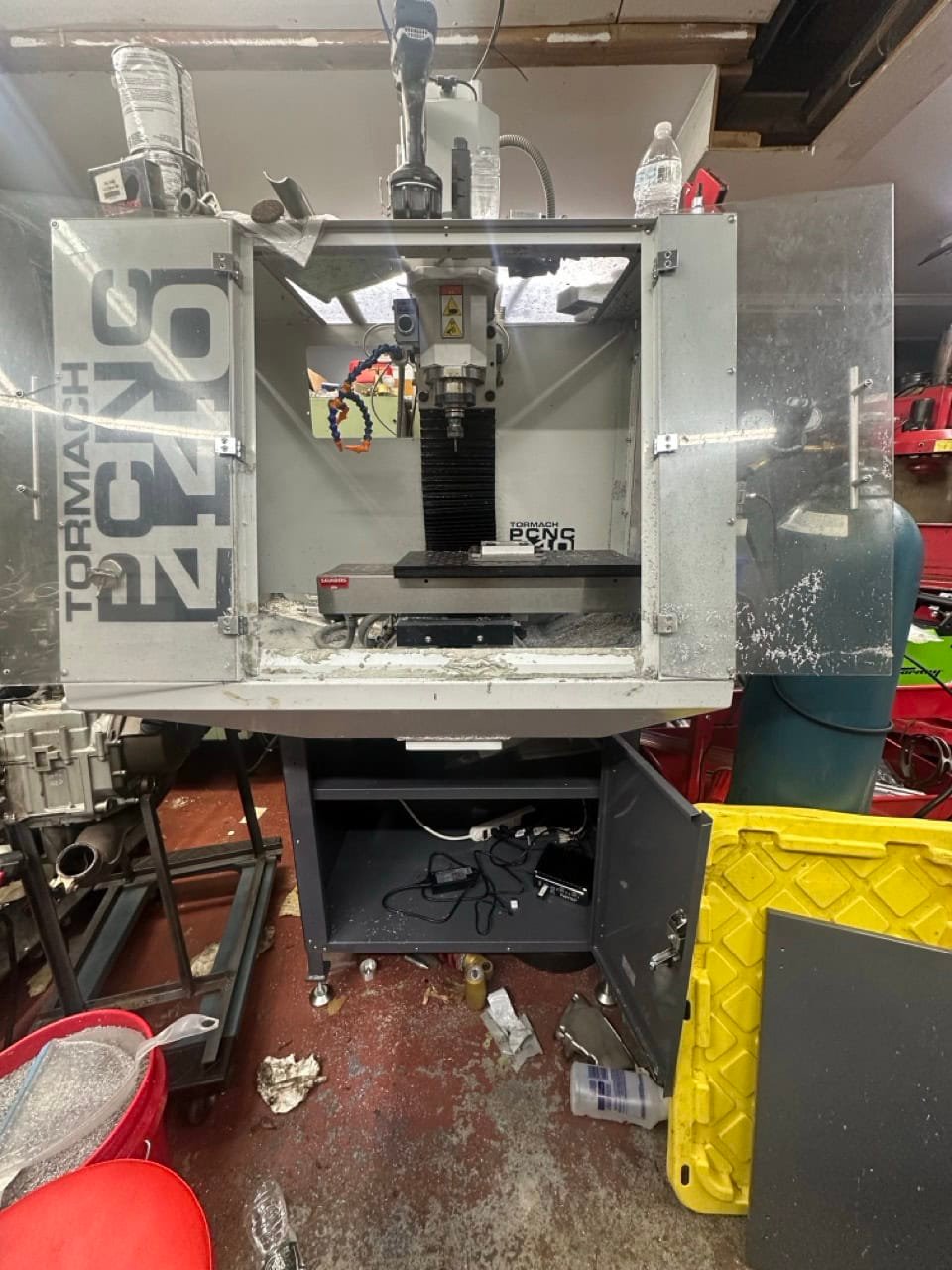

Tormach PCNC 440 VMC, 2023 – Power Drawbar, Rigid Tap

X-Axis Travel: 10″ Y-Axis Travel: 6.25″ Z-Axis Travel: 10″ Table Size: 18″ × 6.3″ Spindle Speed: 10,000 RPM Spindle Motor: 1.5 HP Spindle Taper: R8 Rapid Traverse: 135 IPM Weight: 600 lbs Dimensions (W × D × H): 36″ × 42″ × 78″ Equipped With: PathPilot Control System Power Drawbar Rigid Tapping Coolant System Manual Tool Changer All Available Manuals

$10,900.00

-

Haas VF-2SS VMC, 2021 – Through Spindle Coolant, Rigid Tapping

Table Size: 36″ x 14″ Table Load Capacity: 1,500 LBS X Axis Travel: 30″ Y Axis Travel: 16″ Z Axis Travel: 20″ Spindle Taper: CAT 40 Spindle Speed: 12,000 RPM Spindle Motor: 30 HP ATC: 30 + 1 Approx. Dimensions: 124.0″ L × 89.0″ W × 107.0″ H Approx. Weight: 7,800 lbs Equipped With: Haas CNC Control Through Spindle Coolant Rigid Tapping Macros Rotation & Scaling M19 Spindle Orient High Speed Machining VPS Editing Media Display Max Memory 1GB Wireless Networking Compensation Tables

$64,900.00

-

HWA Series Best Air-cooled Laser Welding Machine – HGSTAR

Air-cooled Laser Welding Machine has the best fiber laser beam, fast welding speed, high quality weld seam, no consumables. it is used for welding carbon steel, stainless steel, aluminum, copper, and other metal plates. now at a discounted price of for sale.

-

HWS series small fiber laser welding machine – HGSTAR

Small fiber laser welding machine has the best fiber laser beam, fast welding speed, high quality weld seam and no consumables. It is used to weld carbon steel, stainless steel, aluminum, copper and other metal plates. Now on sale at a discounted price.

-

HW series best handheld fiber laser welding machine – HGSTAR

Handheld fiber laser welding machine has the best fiber laser beam, fast welding speed, high quality weld seam, no consumables. it is used for welding carbon steel, stainless steel, aluminum, copper, and other metal plates. now at a discounted price of for sale.

-

Smart-WWRB1000 Deburring machine |

Model: Smart-WWRB1000 Category: Deburring machine Brand Name: HG Smart Uses: The HG deburring machine is used in the belt sanding station to increase the automatic corrective function, real-time detection of the position of the sanding belt and corrected with the following advantages.Ensure that the sanding station can run smoothly in high-speed operation.Adjustment through the cylinder movement, running more smoothly, will not happen jamming and other accidents.No need to make multiple adjustments to improve production efficiency.

-

Laser cutting machine with automatic loading

The Smart-HCL30 CNC fiber laser cutting machine with automatic loading and unlaoding system is a product manufactured by HGStar in accordance with international export standards. This series of products is the preferred model for automatic loading and unloading in the metal processing industry, with ultra-high loading and unloading efficiency, extremely low operating costs, and super adaptability.

-

-

CNC Bending Machine – HGSTAR

CNC Bending Machine has the best fiber laser beam, fast welding speed, high quality weld seam and no consumables. It is used to weld carbon steel, stainless steel, aluminum, copper and other metal plates. Now on sale at a discounted price.

-

Smart CYP series laser bending machine – HGSTAR

Its primary purpose is to bend workpieces into specific shapes or angles, using linear or rotational movements to achieve bending. The advantages of a bending machine are durability, increased speed, cost-effectiveness with various steel plates, pipes, and rebars. Additionally, this CNC bending machine can perform multiple actions.

-

Metal & Nonmetal Laser Cutter with 300W CO2 Laser Tube | HGSTAR

Metal & nonmetal laser cutting machine with 300W CO2 laser tube is a new designed laser cutter for stainless steel, alloy, acrylic, leather, plywood, MDF, wood

-

Smart HMP Series Fiber Laser Marking Machine For Metal

Smart HMP Series Fiber Laser Marking Machine For Metal is a high-tech product that uses advanced laser technology to mark various materials on metal surface with high precision and accuracy. This kind of desktop fiber laser developed by HGSTAR aims to meet the demand for simple, compact, flexible

Our Laser Series

Laser Welding Machine

Tube Cutting

Laser Engraving

Laser Cleaning Machine

Sheet Cutting

Bending Machine

Featured Products

-

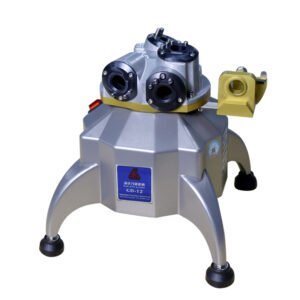

Universal Tool Grinder

Cost-effective End Mill Sharpening Machine for sale – Qiandao Machinery Manufacturing

-

Internal And Cylindrical Grinding Machine

GD-01TP-A Customized small automatic outer diameter punch grinding machine – Qiandao Machinery Manufacturing

-

Internal And Cylindrical Grinding Machine

GD-5020A/B Cylindrical Grinding Machine – Qiandao Machinery Manufacturing

-

Vertical Machining Centers

Tormach PCNC 440 VMC, 2023 – Power Drawbar, Rigid Tap

-

Vertical Machining Centers

Haas VF-3YT 50 Taper CNC VMC, 2007 – 4-Axis, 30 ATC, 2-Speed Gearbox

-

Sheet and Tube Laser Cutting Machine

Enclosed Type Metal Sheet and Tube Fiber Laser Cutting Machine – HGSTAR

-

Surface Grinder Machine

Precision Surface Grinder Machine for sale – Qiandao Machinery Manufacturing

-

Laser Cutting Machine

2023 Best Fiber Laser Metal Cutting Machine for Sale | HGSTAR

-

Surface Grinder Machine

Precision Surface Grinder Machine GD-450G – Qiandao Machinery Manufacturing

-

Wheel CNC Machine

High Quality Economical Car Wheel Lathe CK6160Q

-

Other grinder machine

GD-100D CNC Automatic Saw Blade Grinding Machine – Qiandao Machinery Manufacturing

-

Centerless grinding machine

High precision centerless grinder machine

-

Portable tool grinder machine

En iyi uç frezeleme kesici taşlama makinesi – Qiandao Makine İmalatı

-

Universal Tool Grinder

GD-600/600S Universal Tool Grinder – Qiandao Machinery Manufacturing

-

Customized CNC Machine

Customized CNC Vertical Wheel Machining Center

-

Other grinder machine

Best precision cut off and grinding machine – Qiandao Machinery Manufacturing

-

Laser Marking Machine

Smart HMP Series Fiber Laser Marking Machine For Metal

-

Laser Cutting Machine

Economical Single-platform Fiber Laser Cutting Machine 1000W 1500W 2000W 3000W| HGSTAR

-

Internal And Cylindrical Grinding Machine

GD-02TP-B Özelleştirilmiş Küçük otomatik iç taşlama makinesi – Qiandao Makine İmalatı

-

Tube Laser Cutting Machine

2025 Best Fiber Laser Tube cutting machine | HGSTAR

Why Choose Us

Convenient and Professional Technical Support

Provide you with convenient, fast and professional technical answers.

Customized Solutions for Enhanced Competitiveness

Provide you with customizable solutions. The customized laser equipment has more core competitiveness in your country and can create value for you efficiently and quickly.

Free Warranty Replacements

Replace any accessories for you free of charge during the promised warranty period. This is also the business philosophy of Smart premium machines that has always been adhering to integrity and service first, which has won the praise of high-quality customers and established a long-term cooperative relationship.

Performance-Based Incentives for Partners

Annual dealers, agents, and brand agents who achieve the performance target stipulated in the annual sales will have additional reward support.

Valued Customer Feedback and Continuous Improvement

We are very happy that Smart premium machines customers provide valuable suggestions and modification plans. We continue to learn and improve to achieve the best plan.

Complimentary Accommodation and Meals for Training Visits

Provide free hotel and catering services for agents, dealers, distributors, etc. when they come to Smart premium machines for training and learning.

Client's feedback

"Excellent service! The team at Smart Premium Machines SL helped us choose the right machine and handled the installation smoothly. Very professional."